Flat Top Chains – Diverse Styles and Customized Production

FTC-01: Flat top chain has smooth surface and high conveying efficiency.

Introduction

Flat top chains, also called flat top chain plate, slat top chain, table top chain plate, it is an efficient chain plate used in the glass industry, food industry, wine and other industries for conveying. The flat top chains can be made of carbon steel, stainless steel or galvanized steel for high tensile strength and bearing load. Compared with balanced weave belt, it supplies a flat and smooth surface for high performance conveying. We can supply you all kinds of flat top chains in different specs and materials. We can customize the flat top chains according to your equipment and requirements.

Flat top chain plate types

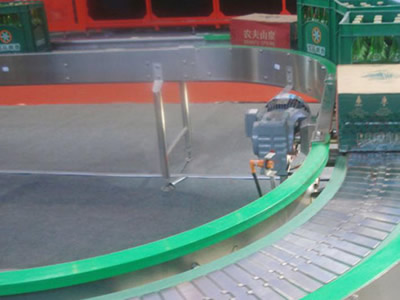

Standard flat top chains are not curved, which is suitable for straight conveying machine. But in some workshops, the space is limited, so the conveying line will be made into L shape, U shape or rectangular shape. So it need adjust the machine for smooth conveying. Here we can supply not only the standard flat top chains, but the side flex flat top chains.

- Straight running flat top chains. Straight flat top chains supplies high loading capacity and smooth surface in the straight conveying machines. It is combined with several regular rectangular chain plates and high pins.

- Side flex flat top chains. Side flex flat top chains are suitable for flex machine, which maybe L shape, U shape or rectangular shape. The side flex flat top chains can ensure fast, smooth and steady conveying. Chain plates of side flex flat top chains have two types: flat edge chain plates and bevel edge chain plates.

- Flat edge chain plates. It is combine with flat edge chain plates and hinge pins. Flat edge chain plates can complete side flex conveying through increase the clearance between high pins. In this way, the neighbor chain plate can permit a certain turning angle to achieve smooth side flex conveying. Flat edge chain plate can not only ensure the smooth and steady side flex conveying, but also the normal conveying for straight running.

- Bevel edge chain plates. The chain plates are made of chain plates with symmetrical bevel edge. The bevel edge can eliminate the interference during side flexing conveying and ensure smooth and high efficient conveying. Additional, there has no any gap when it is used in the flex position. The angle of bevel plate and the pin clearance decide the turning radius.

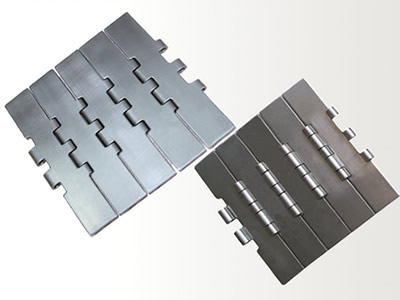

FTC-02: Straight running flat top chain.

FTC-03: Side-flex flat top chain.

FTC-04: Flat edge flat top chain.

FTC-05: Bevel edge flat top chain.

Hinge pin types

It is the important component of flat top chain plate system. It support and connect the chain plates and ensure smooth and high efficient conveying no matter in straight running or side flex running. It has different types for your choice.

The hinge pins can be divided into single hinge pin and double hinge pin according to different width and detailed requirements of customers and equipment.

- Single hinge pin. Single hinge pin design with simple structure and lighter weight is suitable for the short width chain plates and light duty loading products.

- Double hinge pin. Double hinge pin design is suitable large span chain plate for higher stability and loading capacity.

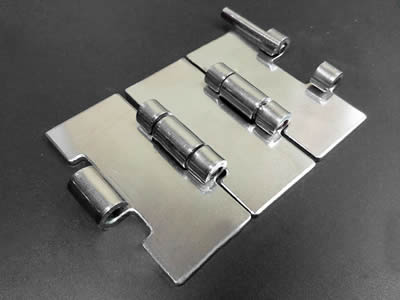

FTC-06: Single hinge pin flat top chain.

FTC-07: Double hinge pin flat top chain.

The hinge pins have different styles, such as standard hinge pins and TAB hinge pins. They are all be customized to suit different machines and driving method.

FTC-08: Standard hinge pin.

FTC-09: TAB hinge pin.

Customization

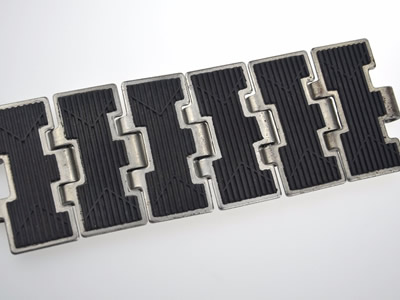

- High friction rubber. High friction rubber can be assembled on the top or bottom of flat top chain. In this way, it can not only improve the high friction of surface, but also protect fragile products from falling down. Commonly, the rubber can be standard thin rubber layer or thick elastic polyurethane rubber. Other types can be customized according to customers' requirements.

- Rubber on chain plate side. Because of the high friction rubber brings, it is also called high friction top chain plates of rubber top chain plates. The rubber can not only supply high friction, it can improve the anti-slip performance for glass bottle and other fragile products conveying.

- Rubber on the hinge pin side. It is a newly and special technology for the rubber assembly. Assemble the rubber between the hinge pins can reduce the friction of hinge pins and extend the service life of hinge pin. Additional, it can reduce the shake during conveying products.

FTC-10: Thin rubber on the chain plate surface.

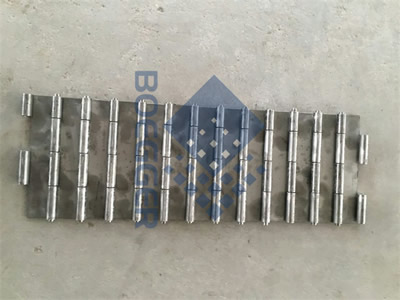

FTC-11: Thick polyurethane on the hinge pin side. - Full wide hinge pin. As we all know, the hinge pin is commonly assembled in the middle position of chain plate, which can be single hinge or double hinge. Sometimes, the hinge pin is assembled on the whole chain plate width, which is similar to the metal plate conveyor belts. The wider hinge pin supplies higher loading capacity for heavy duty applications. Moreover, flat top chain plate with whole wide hinge pins can support the chain plate and ensure more smooth and stable conveying than the traditional chain plate.

FTC-12: Central hinge pins flat top chain.

FTC-13: Full wide flat top chain.

Specification

- Material: commonly is carbon steel and stainless steel. Aluminum and galvanized steel can be customized.

- Chain plate thickness: 6 Gauge – 13Gauge (2.5 mm – 5 mm).

- Chain plate width: 3" (76.2 mm), 3-1/4" (82.6 mm), 3-1/2" (88.9 mm), 4" (101.6 mm), 4-1/2" (114.3 mm), 5" (127 mm), 6" (152.4 mm) or 7-1/2" (190 mm). Customized width available.

- Belt length: MOQ – 3 m

- Pin/Rod diameter: 5–8 mm.

- Pin pitch: 25.4 mm, 31.75 mm, 38.1 mm and 63.5 mm.

- Detailed specifications and drawings, see the PDF profile: Flat Top Chain Specifications

Features

- High performance. The flat and smooth surface has little friction for high performance conveying.

- High friction. The rubber top chain plates improve the surface chain to protect products from falling down.

- Smooth and steady conveying. Straight running and sideflexing types to suit different conveying line.

- Easy cleaning and low maintenance. Clean them with flow water or soak in water for easy and fast cleaning.

- Corrosion and rust resistance. Stainless steel and other anti-corrosive materials ensure the flat op chain a long service life.

- High load capacity. The chain plates have larger loading surface than balanced weave conveyor belts and other conveyor belts made of steel wires. In this way, it can load more products and for heavy duty applications.

- Customization. All the products can be customized according to your requirements and drawing.

- Wide range of applications. It serves for lots of conveying applications in many industries, such as beverage, food processing, glass bottling filling.

Application

Flat top chains have a wide range of applications, details are as follows:

- Food processing.

- Quick frozen products.

- Food industry.

- Soft drinks industry.

- Breweries.

- Glass bottling filling.

- Wire industry.

- Dairy.

- Cheese production.

- Beer production.

- Incline conveying.

- Canning.

- Pharmaceutical packing.

FTC-14: Flat top chain for beer conveying.

FTC-15: Flat top chain for juice bottles conveying.

Inquiry for Our Product

Boegger Industech Limited

Email: sales@steelconveyorbelt.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.