Metal Chain Plate Conveyor Belt – Smooth, Perforated and Convex Surface

Metal chain plate conveyor belts, also called hinged steel belting, plate link conveyor belts, chain plates are a type of conveying device made of steel plates and hinge pins or connection rods. Compared with wire belts, the metal plate conveyor belt can supply larger contacting area, flat and smooth surface for drying, sorting and conveying. We can supply you all types and specs of metal plate conveyor belt, browse the following types and decide which one is suitable for you.

Metal chain plate conveyor belt materials

- Carbon steel metal plate conveyor belt.

- Stainless steel plate chain conveyor belt.

- Galvanized steel plate chain conveyor belt.

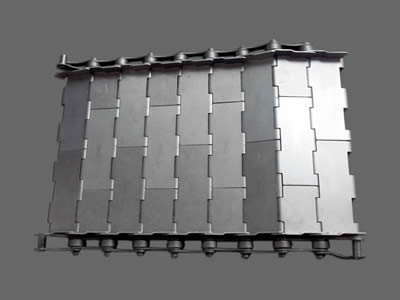

MCP-01: Carbon steel metal chain plate conveyor belt.

MCP-02: Stainless steel metal chain plate conveyor belt.

Specifications of metal plate conveyor belt

- Material: carbon steel, SS 201, SS 304, SS 316.

- Plate thickness: 0.8 mm, 1 mm, 1.2 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm.

- Connection rod diameter: 5 mm, 6 mm, 8 mm, 10 mm, 12 mm.

- Rod pitch: 19.05 mm, 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 76.2 mm.

- Chain plate width: 200 mm to 4,000 mm.

- Belt length: customized.

- Surface treatment: hot dipped galvanized, blacking.

Detailed specifications: refer to the Table 1.

Metal chain plate conveyor belt types and shapes

Flat plate conveyor belt types

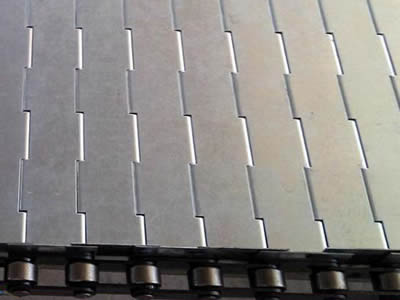

Flat plat conveyor belt, also called perforated non-perforated conveyor belt is the simple structure of metal plates, it can be made of flat chain plates, which is similar to the flat top chains, or channel steel.

- Flat bar chain plate conveyor belt.

- Channel steel chain plate conveyor belt.

MCP-03: Flat bar chain plate conveyor belt.

MCP-04: Channel steel chain plate conveyor belt.

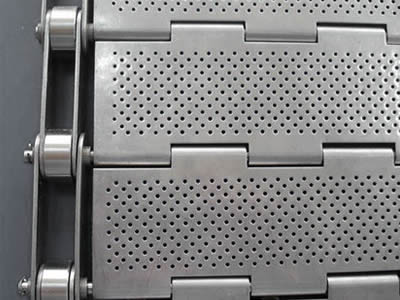

Perforated plate conveyor belt

Perforated plate is combined with continuously perforated chain plates, the holes on the surface supply excellent heat dissipation performance for conveying products, such as biscuits, breads and other hot products. Perforations allow the opening in the belt to vary from zero to very large.

Perforated plate conveyor belt can be made into different patterns. You can choose the suitable pattern to suit your application and detailed using conditions. The aperture of perforated holes can be customized according to your requirements.

MCP-05: Staggered round hole perforated metal plate conveyor belt.

MCP-06: Straight round hole perforated metal plate conveyor belt.

MCP-07: Vertical strip hole perforated metal plate conveyor belt.

MCP-08: Horizontal strip hole perforated metal plate conveyor belt.

MCP-09: Slot hole perforated metal plate conveyor belt.

MCP-10: Square holes perforated metal plate conveyor belt.

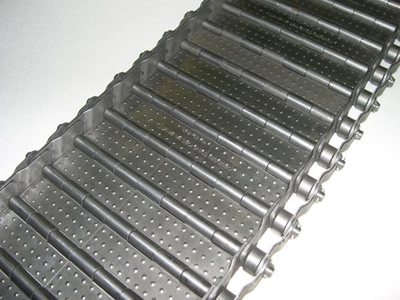

Convex chain plate conveyor belt.

The chain plate surface are produced into several raised round ball shapes in different diameters. The raised or convex surface supplies excellent anti-slip performance to prevent conveying products from falling down to the ground. The convex chain plates can be added with transverse baffles and side plates for sorting and protecting.

MCP-11: Convex chain plate conveyor belt with transverse baffle.

MCP-12: Convex chain plate conveyor belt with side plates.

Customization of metal plate conveyor belt

Metal plates belts with side plates

Side plates are optional accessory during chain plate production. The side plates can be made into various designs and height to protect conveying products from falling down during elevation or decline. It can be divided into 2 lane, 3 lane and dog leg types for your choice.

MCP-13: Two lane side plate chain plate conveyor belt.

MCP-14: Three lane side plate chain plate conveyor belt.

MCP-15: Dog leg side plate chain plate conveyor belt.

Side plate installation types

- Welded type. The side plates are welded onto the connecting rod during production. It is solid and fixed type.

- Fitted to rods. The side plates and connected onto the connecting rod through fittings. It is flexible and easy to replace.

MCP-16: Welded side plate installation type.

MCP-17: Fitted to rods installation type.

Metal plate belts with transverse baffle plate.

We can supply chain plate conveyor belt with transverse baffles. The transverse baffles can be fitted or welded onto the chain plates during production. This design can make the sorting and conveying easy and convenient. The transverse baffle can be made into different types and sizes.

- Flat plate transverse baffle.

- Perforated plate transverse baffle.

- Waving plate transverse baffle.

MCP-18: Flat plate transverse baffle.

MCP-19: Perforated plate transverse baffle.

MCP-20: Waving plate transverse baffle.

Metal chain plate conveyor belt transportation forms

Metal chain plate conveyor belt can be made into both direct transmission types and turning types. The turning type are suitable for the conveyors in L shape, U shape and rectangular shapes.

- Direct transmission chain plate conveyor belt.

- Turning chain plate conveyor belt.

MCP-21: Direct transmission – climbing chain plate conveyor belt.

MCP-22: Turning chain plate conveyor belt.

Features of metal plate conveyor belt

- Stable operation. The flat and smooth surface supplies large conveying surface and stable conveying.

- Convenient installation. The installation of metal plate conveyor belt has simple structure, which can be installed and replaced conveniently and fast.

- Suitable for medium and heavy load transportation. The metal plate conveyor belts have large conveying surface and they can self support in heavy duty applications.

- Corrosion and rust resistance. Various anti-corrosive materials and surface treatments ensures the metal plate conveyor belts corrosion and rust resistance. It can be used in harsh environments and arduous conditions.

- Durable and long service life. The material of metal plate conveyor belt is tough, which can be used in good condition for long service life.

Applications of metal plate conveyor belt

- Transporting.

- Drainage.

- Sorting.

- Elevating.

- De-elevating.

- Waste treatment.

- Blanching.

- Drying.

Accessories of metal chain plate conveyor belts

Chains and sprockets are important accessories in the whole conveyor belt system. They can ensure the smooth and stable conveying and improve conveying efficiency. Here is the brief introduction of them, detailed types and styles refer to the Chains and Sprocket.

Chains

Chains are the motivation of metal chain plate conveyor belt. It drives the metal chain plate conveyor belt and ensures smooth and stable conveying no matter in level or lifting, straight or turning conveying process. It has two types during installation.

- Chains with welded washer.

- Chains with cotter pin.

MCP-23: Welded washer chains on chain plate conveyor belt.

MCP-24: Cotter pin chains on chain plate conveyor belt.

Sprocket

Sprocket can be made into single pitch sprocket and double pitch sprocket to suit the chain types. They also have different types and specs for your choice.

- Single pitch sprocket.

- Double pitch sprocket.

MCP-25: Single pitch sprocket.

MCP-26: Double pitch sprocket.

| Item | Chain Pitch (mm) |

Rod Diameter (mm) |

Plate Thickness (mm) |

|---|---|---|---|

| MCPB-01 | 25.4 | 5 | 1.0 |

| MCPB-02 | 25.4 | 6 | 1.0 |

| MCPB-03 | 25.4 | 6 | 1.5 |

| MCPB-04 | 31.75 | 6 | 1.0 |

| MCPB-05 | 31.75 | 6 | 1.5 |

| MCPB-06 | 31.75 | 8 | 2.0 |

| MCPB-07 | 38.1 | 6 | 1.0 |

| MCPB-08 | 38.1 | 6 | 1.5 |

| MCPB-09 | 38.1 | 8 | 1.0 |

| MCPB-10 | 38.1 | 8 | 1.5 |

| MCPB-11 | 38.1 | 8 | 2.0 |

| MCPB-12 | 50.8 | 6 | 1.2 |

| MCPB-13 | 50.8 | 8 | 1.0 |

| MCPB-14 | 50.8 | 8 | 1.5 |

| MCPB-15 | 50.8 | 10 | 2.0 |

| MCPB-16 | 50.8 | 10 | 3.0 |

| MCPB-17 | 63.5 | 10 | 2.0 |

| MCPB-18 | 63.5 | 10 | 1.5 |

| MCPB-19 | 63.5 | 10 | 3.0 |

| MCPB-20 | 80 | 8 | 1.5 |

| MCPB-21 | 80 | 8 | 2.0 |

| MCPB-22 | 80 | 10 | 2.0 |

| MCPB-23 | 80 | 10 | 2.5 |

| MCPB-24 | 100 | 10 | 1.5 |

| MCPB-25 | 100 | 10 | 2.0 |

| MCPB-26 | 100 | 14 | 2.0 |

| MCPB-27 | 100 | 14 | 3.0 |

| MCPB-28 | 101.6 | 10 | 4.0 |

| MCPB-29 | 106.6 | 14 | 4.0 |

| MCPB-30 | 125 | 20 | 3.0 |

Inquiry for Our Product

Boegger Industech Limited

Email: sales@steelconveyorbelt.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.