Multi Types Oven Mesh Belts for Biscuit, Cookie and Bread Baking

Before the biscuits are transferred into baking oven, the biscuits will be shaping and design by cutting dies, they are very soft and loose and need flat surface for backing. Additional, the oven temperature is very high, so we should adopt the extremely safe and temperature resistance oven mesh belt material and types.

oven mesh belt, also called biscuit baking belt, baking conveyor belt, is a multi-type belt for biscuit, cookie, bread and other food baking in the oven. They can be made of stainless steel, carbon steel or copper, which have excellent temperature resistance performance. Here we will introduce you several oven mesh belts for your choice.

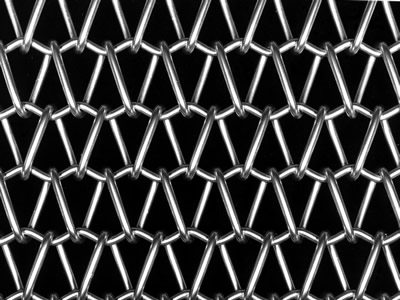

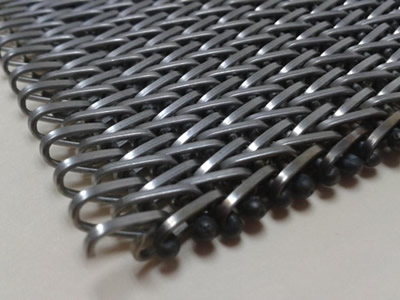

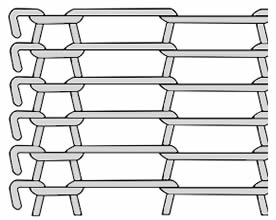

Flat rolled baking belt

Flat rolled baking belt, features its Z shape wire pattern and durable and long lasting material. It is specially designed for biscuit & cookies baking plants. The carbon steel or stainless steels are woven articulated in to one another and then pressed it to get a flatted surface, which is flatter than other belts. This unique design allows free heat, air, gas circulation and helps for rapid drying and baking. Additional, it has a greater longitudinal flexibility to allow the bending surface.

OMB-01: Stainless steel flat rolled baking belt for excellent temperature resistance.

OMB-02: Flat rolled oven mesh belt supplies flattest surface for biscuit conveying.

Specifications of flat rolled baking belt

- Material: carbon steel and stainless steel.

- Wire gauge: 16 gauge (1.5 mm), 17 gauge (1.38 mm), 18 gauge (1.2 mm) and 20 gauge (0.9 mm).

- Thickness of belt: 2.2 mm to 3.0 mm.

- Maximum width: 1.8 m.

- Edge of conveyor: welded or bended.

| Item | Wire Diameter (mm) |

Belt Thickness (mm) |

Maximum Width (mm) |

Min. Drum Diameter (mm) |

Breaking Strength |

|---|---|---|---|---|---|

| FROB-01 | 1.38 | 2.5 to 3.0 | 1800 | 300 | 260 |

| FROB-02 | 1.28 | 2.2 to 2.5 | 1550 | 300 | 240 |

| FROB-03 | 1.38 | 2.5 to 3.0 | 1800 | 300 | 260 |

| FROB-04 | 1.28 | 2.2 to 2.5 | 1550 | 300 | 240 |

Features of flat rolled baking belt

- Lightweight, reduced size and small belt thickness.

- Low heat inertia and good air circulation.

- Smooth belt surface.

- Durable and long lasting material.

- Corrosion and rust resistance.

- Withstand up to 400 °C.

- Width up to 1800 mm.

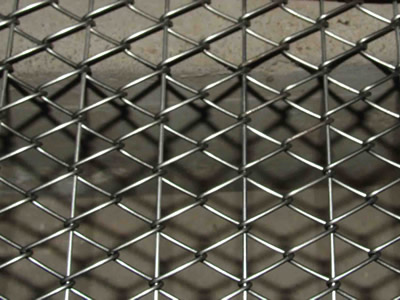

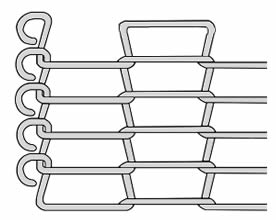

Balanced weave belt

Balanced weave belt consists of left and right hand spiral coils. They are interlocked by crimped or straight wires. It can supply even surface for baking biscuits, cookies and other conveying products.

Balanced weave conveyor belt is made of carbon steel, copper, brass or stainless steel materials, which can supply long and durable lifespan. The regular meshes, which supplies even surface to convey products. The left and right hand spirals are interlocked by the crimped or straight wires. It has a simple yet effective design.

OMB-03: Round wire balanced weave oven mesh belt.

OMB-04: flat wire balanced weave oven mesh belt.

| Item | Spiral Wire Pitch | Cross Rod Pitch | Spiral Wire Diameter | Cross Wire Diameter |

|---|---|---|---|---|

| BWOB–01 | 4 mm | 4 mm | 0.9 mm – 1.2 mm | 1.2 mm – 1.6 mm |

| BWOB–02 | 5 mm | 6.4 mm | 0.9 mm – 1.2 mm | 1.2 mm – 1.6 mm |

| BWOB–03 | 5 mm | 5 mm | 0.9 mm – 1.6 mm | 1.2 mm – 1.6 mm |

| BWOB–04 | 6 mm | 6 mm | 0.9 mm – 1.6 mm | 1.2 mm – 1.6 mm |

| BWOB–05 | 6 mm | 8 mm | 0.9 mm – 1.2 mm | 1.2 mm – 1.6 mm |

| BWOB–06 | 6 mm | 10 mm | 0.9 mm – 1.6 mm | 1.2 mm – 1.6 mm |

| BWOB–07 | 8 mm | 12 mm | 1.2 mm – 2.0 mm | 1.2 mm – 2.5 mm |

| BWOB–08 | 8 mm | 13 mm | 1.2 mm – 2.0 mm | 1.2 mm – 2.5 mm |

| BWOB–09 | 8 mm | 15 mm | 1.2 mm – 2.0 mm | 1.2 mm – 2.5 mm |

| BWOB–10 | 11 mm | 15 mm | 1.2 mm – 2.0 mm | 1.2 mm – 2.5 mm |

| BWOB–11 | 11 mm | 20 mm | 1.6 mm – 3.0 mm | 1.6 mm – 3.0 mm |

| BWOB–12 | 11 mm | 25 mm | 1.6 mm – 3.0 mm | 1.6 mm – 3.0 mm |

| BWOB–13 | 11 mm | 27 mm | 1.6 mm – 3.0 mm | 1.6 mm – 3.0 mm |

| BWOB–14 | 15 mm | 20 mm | 1.6 mm – 3.0 mm | 1.6 mm – 3.0 mm |

| BWOB–15 | 15 mm | 25 mm | 1.6 mm – 3.0 mm | 1.6 mm – 3.0 mm |

| BWOB–16 | 22 mm | 23 mm | 1.6 mm – 3.0 mm | 1.6 mm – 3.0 mm |

| BWOB–17 | 22 mm | 33 mm | 1.6 mm – 3.0 mm | 2.0 mm – 4.0 mm |

Features of balanced weave belt

- High temperature resistance.

- Corrosion and rust resistance.

- Low maintenance cost.

- Flat surface for shape maintaining.

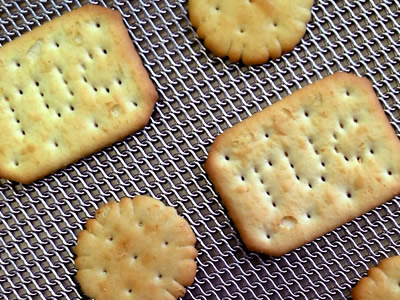

OMB-05: Balanced weave oven mesh belt for biscuit baking.

OMB-06: Balanced weave oven mesh belt for cookie baking.

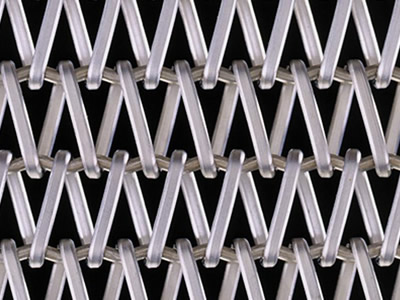

Compound weave belt

Compound weave belt has left and right spirals fitted closely together for a smooth, dense surface for conveying very fine or small products as well as unstable products needing very flat surfaces and considerable product support. Compared with balanced weave belt, the compound weave has closer space for supplying more stable surface.

Compound weave belt is commonly made of carbon steel or stainless steel materials, which has high loading capacity and tough structure. Compound weave belt can be made of round or flat wires for different applications.

OMB-07: Round steel wire compound weave oven mesh belt.

OMB-08: Flat steel wire compound weave oven mesh belt.

Specifications of compound weave belt

- Material: carbon steel or stainless steel.

- Wire type: flat wire or round wire.

| Item | Coil Pitch (mm) |

Coil Wire Diameter (mm) |

Cross Wire Pitch (mm) |

Cross Wire Diameter (mm) |

Number of Cross Wires Per Coil (mm) |

|---|---|---|---|---|---|

| CWOB-01 | 5.08 | 1.22 | 3.05 | 1.22 | 3 |

| CWOB-02 | 11.29 | 2.03 | 4.35 | 2.03 | 4 |

| CWOB-03 | 10.16 | 2.03 | 5.08 | 2.64 | 4 |

| CWOB-04 | 4.24 | 0.91 | 2.24 | 1.22 | 4 |

| CWOB-05 | 8.47 | 1.63 | 3.63 | 1.63 | 4 |

| CWOB-06 | 6.35 | 1.22 | 2.82 | 1.22 | 4 |

| CWOB-07 | 8.71 | 1.6 × 1.3 | 3.9 | 1.63 | 5 |

Features of compound weave belt

- Small openings for conveying fine and small items.

- High temperature resistance. It can withstand the high temperature of oven and ensure stable conveying.

- Long lifespan. The tough material and solid structure make the compound weave belt a long service life.

- Round or flat wires to suit more applications for different use.

OMB-09: Compound weave oven mesh belt for biscuit baking.

OMB-10: Compound weave oven mesh belt for cookie baking.

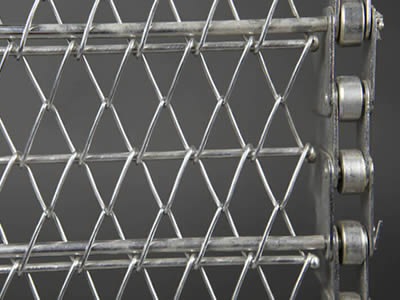

Chain link conveyor belt

Chain link conveyor belt has simple and flexible structure. It is commonly made of carbon steel, stainless steel or copper. They all have high loading capacity and durable life. The chain link conveyor belt is combined with several spiral coils, which can be made into reinforced or double reinforced chain link conveyor belt to suit the heavy duty applications.

OMB-11: Standard chain link oven mesh belt.

OMB-12: Reinforced chain link oven mesh belt.

OMB-13: Double reinforced chain link oven mesh belt.

OMB-14: chain link oven mesh belt is driven by chains.

| Item | Wire Diameter (mm) |

Cross Rod Diameter (mm) |

Spiral Coil Quantity | Belt Thickness (mm) |

|---|---|---|---|---|

| Standard Chain Link Conveyor Belt | ||||

| CLOB-01 | 2.8 | - | 84 | 10 ± 0.5 |

| CLOB-02 | 2.2 | - | 100 | 8 ± 0.4 |

| CLOB-03 | 1.6 | - | 69 | 7 ± 0.4 |

| CLOBS-04 | 1.2 | - | 100 | 6.5 ± 0.4 |

| CLOBS-05 | 1.1 | - | 182 | 6 ± 0.4 |

| CLOBS-06 | 0.9 | - | 153 | 6 ± 0.4 |

| Rod Reinforced Chain Link Conveyor Belt | ||||

| CLOBR-01 | 3.5 | 4 | 25 | 14 ± 0.6 |

| CLOBR-02 | 3.5 | 3.5 | 50 | 14 ± 0.6 |

| CLOBR-03 | 2.8 | 2.8 | 50 | 11 ± 0.5 |

| CLOBR-04 | 2.0 | 2.0 | 100 | 9 ± 0.4 |

| CLOBR-05 | 1.6 | 1.6 | 100 | 7 ± 0.4 |

| CLOBR-06 | 0.9 | 0.9 | 200 | 6 ± 0.4 |

| Double Reinforced Chain Link Conveyor Belt | ||||

| CLOBD-01 | 3.5 | 3.5 | 100 | 14 ± 0.6 |

| CLOBD-02 | 2.8 | 2.8 | 132 | 12 ± 0.5 |

| CLOBD-03 | 2.8 | 2.8 | 118 | 11 ± 0.5 |

| CLOBD-04 | 2.0 | 2.0 | 200 | 9 ± 0.4 |

| CLOBD-05 | 1.6 | 1.6 | 250 | 7.5 ± 0.4 |

OMB-15: Chain link oven mesh belt for biscuit baking.

Features of chain link conveyor belt

- Simple. Several spiral coils contribute simple structure.

- Suitable for heavy duty applications.

- Various materials for choice. Carbon steel, stainless steel and copper.

- Flexible. It is much more flexible than compound weave belt and balanced weave belt.

- High temperature resistance. It can ensure stable and efficient conveying in high temperature conditions.

- Durable and long service life. All types chain link oven mesh belt have high quality material and stable structure for long lifespan.

- Little maintenance cost. It can save time and effort costs for maintenance.

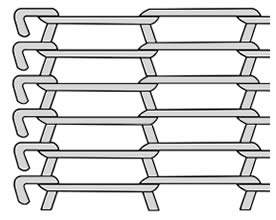

Rod network belt

Rod network belt has the simplest structure among all the oven mesh belt. It is made of carbon steel or stainless steel, which has excellent temperature resistance performance to withstand the high temperature in the oven and ensure stable and efficient conveying.

Rod network belt is constructed by several loop wires and then be formed into different edge. Simple structure supplies lightweight and economical features for the oven mesh belt.

OMB-16: Flat surface and large open area supplies high conveying performance and good air circulation.

OMB-17: Barriers on the rod network oven mesh belt is convenient to protecting and sorting goods and other items.

OMB-18: Single loop edge rod network oven mesh belt.

OMB-19: Double loop edge rod network oven mesh belt.

OMB-20: C shape edge rod network oven mesh belt.

| Item | Wire Diameter (mm) |

Pitch (mm) |

Open Area (%) |

Edge Type |

|---|---|---|---|---|

| BFFCB-01 | 0.9 | 4.24 | 77 | single/double |

| BFFCB-02 | 0.9 | 5.64 | 82 | single/double |

| BFFCB-03 | 1.0 | 5.5 | 79 | single/double |

| BFFCB-04 | 1.0 | 5.6 | 79.5 | single/double |

| BFFCB-05 | 1.27 | 4.3 | 67 | single |

| BFFCB-06 | 1.27 | 5.5 | 73 | single/double |

| BFFCB-07 | 1.27 | 6.0 | 76 | single/double |

| BFFCB-08 | 1.27 | 6.35 | 77 | single/double |

| BFFCB-09 | 1.27 | 7.26 | 80 | single/ double/C-shape |

| BFFCB-10 | 1.40 | 6.40 | 76 | single/C-shape |

| BFFCB-11 | 1.60 | 7.26 | 75 | single/ double/C-shape |

| BFFCB-12 | 1.83 | 12.00 | 81 | single |

| BFFCB-13 | 1.83 | 12.70 | 82 | single/C-shape |

| BFFCB-14 | 2.08 | 9.60 | 75 | single/C-shape |

| BFFCB-15 | 2.35 | 12.70 | 78 | single/C-shape |

| BFFCB-16 | 2.35 | 20.32 | 85 | single |

| BFFCB-17 | 2.80 | 12.70 | 72 | single/C-shape |

Features of rod network oven mesh belt

- Large open area.

- Lightweight.

- Economical.

- High temperature resistance.

- Good air circulation.

- Durable and long lifespan.

- Easy to clean and low maintenance cost.

OMB-21: Rod network oven mesh belt for bread baking.

OMB-22: Rod network oven mesh belt for biscuit baking.

Inquiry for Our Product

Boegger Industech Limited

Email: sales@steelconveyorbelt.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.